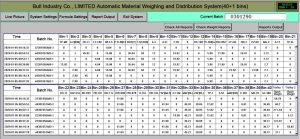

Brake Pads Automatic Material Weighting and Mixing System

描述

刹车片自动配料配料系统用于配料前自动称量原材料。 该系统根据PLC中保存的摩擦材料配方全自动运行。 如果操作员选择保存的配方,它会自动称重并收集不同称重的材料,然后排放到链接的混合器中。

Brake Pads Automatic Material Weighting and Mixing System is used for weighing raw materials automatic before mixing. This system operates fully automatic base on the friction material formulation saved in PLC. If operator selects saved formulation, it automatically weighing and collecting different weighed material and then discharge to the linked Mixers.

- 电子秤整个过程由计算机控制;

- The whole process of electronic weighing range is controlled by computer;

- 自动化程度高,配方保密性好,数据存储跟踪,可打印输出;

- High degree of automation, good formula confidentiality, data storage track, it could print out;

- 系统部件相对独立,布局灵活,闸门位置不受限制;

- System components are relatively independent, flexible layout, unrestricted gate position;

- 控制室与系统隔离,工作环境良好;

- Control room is in isolation with the system under good working environment;

- 拥有完善的监控系统,显示配料全过程监控;

- Has a comprehensive monitoring system to show the whole process of monitoring the ingredients;

- 封闭式防尘设计。

- Closed dust proof design.

- 配料速度快,可满足2x1200L搅拌机或4x600L搅拌机以上的需求。

- Fast batching speed, can meetup the demand of more than 2x1200L Mixers or 4x600L Mixers.

- 配料精度高:每种物料的精度可达0.2%,系统具有重新称重功能

- High batching accuracy: the accuracy of each material can reach 0.2%, and the system has the function of reweighing

- 自动化程度高:纤维、钢丝绒等流动性差的物料也可自动称重。

- High degree of automation: materials with poor fluidity such as fibers,steel wool can also be automatically weighed.

- 具有防错送料功能和料位报警提醒功能。

- With feeding error prevention function and material level alarm reminder function.

- 可查看、打印报告,具有可追溯性.

- Can view and print reports, with traceability

技术参数:

Technical Parameters:

- 物料箱:20至50个箱,根据用户定制

- Material bins: 20to 50 bins, customized to user’s

- 配料精度:≤2%; ±1公斤

- Batching accuracy: ≤2%; ±1KG

- 150公斤称重速度:4-5分钟。

- Weighing speed for 150 kgs: 4-5 minuets.

- 物料性质:粉状、粒状、短纤维

- Material properties: powdery, granular, short fiber

- 最小重量:15 克

- Minimum weight: 15 g

- 最大重量:200公斤

- Maximum weight: 200 kg

- 压缩空气压力:0.5~0.7Mpa。

- Compressed air pressure: 0.5 ~ 0.7 Mpa.

- 压缩空气 Amouna:0.A ~ 0.4 with/from。

- Compressed air amount: 0.2 ~ 0.4 m3/ min.

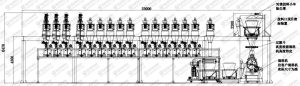

第 1 部分:材质箱层

Part 1: Materials Bins Layer

第 2 部分:第一个称重机制

Part 2: First Weighing Mechanism

第 3 部分:带有第二称重机构的轨道和手推车

Part 3: Track and Trolley with 2nd Weighing Mechanism

第 4 部分:混料机

Part 4: Mixing Machines

第 5 部分:混合料分离系统

Part 5: Mixes Separating System

- 数据报表查看及打印

- Data report check and print

- 图一:3层设计,适合高层建筑结构,手推车无需举升。

- Drawing 1, 3-floor design, suitable for high building structure, trolley no need to be lift up.

- 图2:2层设计,适合低层建筑结构,小车需升降至2层

- Drawing 2, 2-floor design, suitable for low building structure, the trolley shall be lift up to the 2ndfloor

- 刹车片自动配料和混合系统

- Brake Pads Automatic Material Weighting and Mixing System

- 系统预制框架平台

- Prefabricated Frame Platform for the System