Automatic CV Brake Linings Press Machines With Material Weighting and Feeding

描述

来令片自动压机组包括混合材料称重和投料机构,配有自动取片机械手,自动化程度高,有效提高生产效率,降低人工成本。

CV Brake Lining Hot Press Machine is an automatic press machine combined with the automatic materials weighting and feeding machine, and an automatic pick-up robot. It not only can increase the working efficient, and also save the labor cost in production.

自动摩擦片筒模秤重送料出料机由上料箱存储(200Kg),双通道高精度自动秤重结构、周转储斗自动哈平装卸托具、送料桁架机械结构、喷涂脱模剂、抽尘密封、全自动数字控制系统、系统润滑部分等组成。

Full automatic CV brake linings hot press machine material weighing and feeding system, including the double way auto weighing machine, transsimation structure with flatenning, feeding trolley, mold release agent, dust collect, with full automatic PLC control.

控制系统由数字伺服控制及伺服单元、气动单元等组成。数控称重送料机手操作简单,安全性高,适宜可代人工之辛劳,机动性高无人为疏忽,人员缺乏困扰,提高生产效率。由于采用数字控制、伺服电机驱动自动系统,就可以实现让生产线完全自动化生产,本系统定位准确快速,送料精度极高,是传统手工摩擦片生产改良之利器。

The PLC control system with servo system is combined with servo unit, penumatic unit and so on. This automatic weighing machine is easy to operate, high safety, to save the labor cost, and increase the production efficiency. Equipped with the digital control, servo motor system, it can make a fully automatic prodcution machine for CV brake linings.

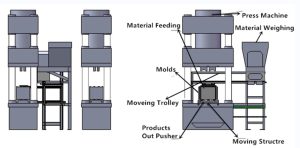

Automatic CV Brake Linings Hot Press Unit Diagram

自动摩擦片筒模秤重送料出料机示意图

Notes: There are no showing of structures of protection, movement, mold release agent, dust prevent

参考图没有表现防护、驱动、喷脱模剂、防尘等机械结构。

技术参数:

Technical Parameters:

- Weighting Accuracy: ≤2.5g/100g

- 称重精度:≤2.5g/100g

- Weighting Range: 1000g~1500g

- 称重范围:1000g~1500g

- Weighting Speed: 2 cycles/50s

- 称重速度:2 循环/50秒

- Complete Cycle Time: 70s

- 整个压制过程单次循环时间:70 秒

- X-Axis : 3000mm. Speed 20m/min;

- X 轴:3000mm. 速度 20m/min;

- Accuracy 0.2mm, Repeat Accuracy 0.2mm

- 精度 0.2mm, 重复精度 0.2mm

- Z1-Axis: 1200mm. Speed 10m/min;

- Z1 轴:1200mm, 速度 10m/分钟

- Accuracy 0.1mm, Repeat Accuracy 0.1mm

- 精度 0.1mm,重复精度0.1mm

- Z2-Axis: 1200mm. Speed 10m/min;

- Z2 轴:1200mm, 速度 10m/分钟

- Accuracy 0.1mm, Repeat Accuracy 0.1mm

- 精度 0.1mm,重复精度 0.1mm

基本结构:

Basic Machine Strcuture:

自动摩擦片筒模秤重送料出料机共有几个机构功能部分组成,分别是 :

The automatic CV brake linings weighing and feeding machine contains different parts:

-自动双通道秤重机, 上储料箱及搅动机构。

-Automatic weghing machine, material lifting box and mixing structure.

-桁架机械结构部分,包括桁架、三轴桁架式机械人。

-Trolley structure, including trolley, 3 axis of robot machine.

设备描述:

Machine Description:

-专用周转储托具自动哈平装卸托具,具有哈平机构、开合功能。另外任意模腔的托盘可以用户提供尺寸我公司可以定制。

– The material moving and feeding structure can flatening function, the size of the feeding can be customized.

-系统在人工设置指定数据下,可以秤重、放料、托盘转运到设定热压机指定的工位、放料到摩擦片压铸模具口腔内。

-The process of material weighing, loading, moveing to the molds, and feeding materials into the molds cavity can be programed on the system.

-系统系统在人工设置指定数据下,可以取料、抓取模芯重新投放到设定摩擦片压铸模具口腔内。

-It has the function of picking up the finished brake linings, and loading the mold core into the molds.

-系统可以按照设定要求对模腔进行喷涂脱模剂。

-The process of mold release agent painting also can be programed.

-上述所有动作采用机械人自动完成。所有行程距离设置在操作屏上完成。只需做一次模拟定位,根据操作屏的数字定位(定位精度0.2mm)。

-These above movements all be processed by robot machine, all procedures can be set up on the touch screen, the accuracy of loacting is 0.2mm.

注意:本设备完成一次4模的秤重、分料、送料只需70秒左右。

Notes: The complete process of production for 4 molds cavities is about 70 seconds.

-机械桁架移动部分采用直线导轨、滚珠丝杆、同步带、钢制桁架机构、润滑系统、移动功能结构、存料托盘等部分组成。

-The moving part of the mechanical truss is composed of linear guide rails, ball screws, synchronous belts, steel truss mechanisms, lubrication systems, mobile functional structures, storage trays, etc.

-电气控制部分我公司采用通用可控机,品牌伺服控制器、品牌气动控制元件、通用继电器、接触器等构建系统。

-In the electrical control part, our company uses universal controllable machines, brand servo controllers, brand pneumatic control components, universal relays, contactors, etc. to build the system.

上料提升机:

Material Lifting:

单台套所用的液压式上料筒上料设备,简单便于操作。同时还有专用上料箱多台套上料设备配套的电动提升上料机设备。

The hydraulic feeding barrel loading equipment used in a single set is simple and easy to operate. At the same time, there are also electric lifting loading machines equipped with special loading boxes and multiple sets of loading equipment.

-液压式上料筒上料设备

-Hydraulic type material loading up machine

-采用液压缸举起方式,举升反转托架把上料塑料桶,把150Kg的摩擦材料投入上料箱中。

-Used by hydraulic lifting type, loading into the 150KG of materials into the weighing machine by reverse structure automatically.

-上料设备设计有防尘封闭罩。

-Dust covered on the material lifting machine.

-上料桶采用标准塑料桶。

-The material lifting box is standard plastic made.

-设备配备有液压站

-Equipped with the hydraulic unit.